Unparalleled speed and accuracy for model-based e-motor design optimization

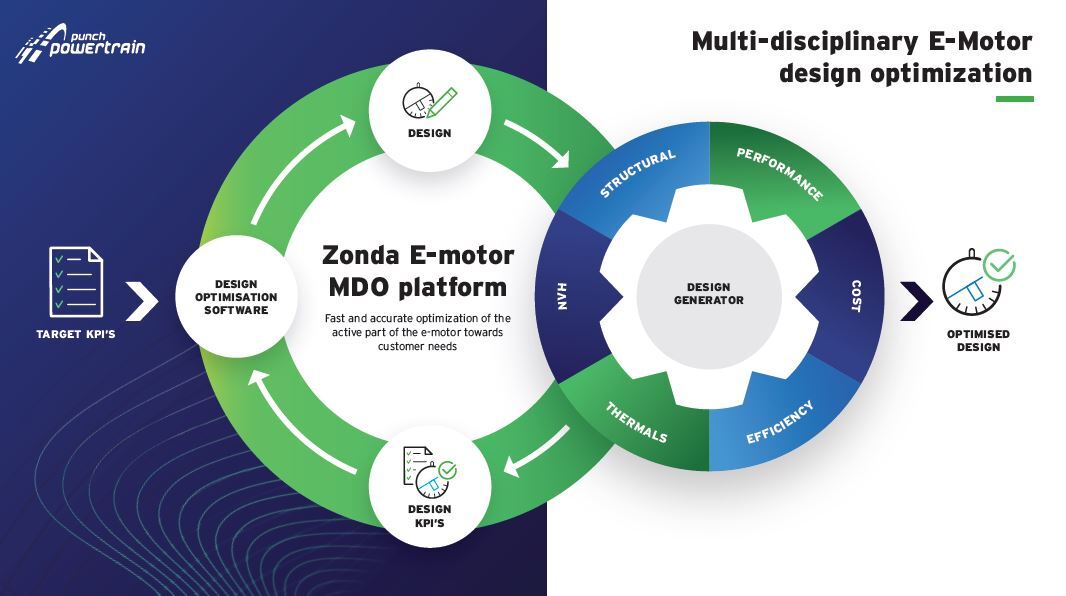

Punch Powertrain designs its products with the highest level of digitization and automation, tailoring to the needs of an increasingly electrifying automotive market. With its new Multidisciplinary Design Optimization Platform, it created a model-based platform that links multiple disciplines related to e-motor design in a time-efficient manner, ensuring high level of accuracy.

Automating model-based design optimization

For the development of its propulsion systems, Punch Powertrain aims at creating the most sustainable design at an affordable cost. In this process, the design must fulfil all requirements set by the customer, for example in terms of power density, efficiency and NVH performance. As a result, the e-motor design engineer faces a variety of design choices related to the geometric shape of the motor and the selection of materials, selecting the most suitable e-motor design from millions of possible combinations.

In order to speed up the search for the best overall designs, Punch Powertrain has created a proprietary, model-based platform that links all calculation models for efficiency, cost, performance, structural integrity, NVH performance and thermal response to advanced optimization software. Today, this platform is applied in the design of e-motors for a crucial part of the company’s portfolio: electric propulsion systems. Using the platform, the engineer is alleviated by taking away the vast majority of manual calculation and optimisation work, resulting in a rapid generation of highly optimized designs.

Trade-offs between key performance indicators

The search for the optimal e-motor design is highly complex, as every design choice may affect multiple key performance indicators. For example, the choice for a more powerful magnet type will be beneficial for performance, but will in turn increase material cost, influence thermal and acoustic performance, and will potentially require a change in rotor and stator.

“Every design decision is a trade-off” states Dr. Ilja Siera, Project Leader in E-drive Innovation at Punch Powertrain and responsible for the creation of the platform. “It is therefore of utmost importance that all trade-offs are laid bare at the earliest possible stage in the design process, preferably while still on the drawing board. Our in-house developed platform enables us to do just that, delivering immediate value to our customers.”

Design optimization tailored to the customer needs

Punch Powertrain’s unique approach enables a tailored design optimization, based on customer needs. The specifications, as defined by the customer, are entered into the platform together with the upper and lower limits of the design space that can be evaluated. For example, if the intended vehicle is designed for highway use, the focus of efficiency calculations is shifted towards the 120kph mark. This further includes applied materials, outer dimensions and internal geometry of the e-motor. The resulting optimisation constraints and objectives, as well as relevant operating conditions, are thereby tailored to the specific customer application.

Speed and accuracy

In order to identify the most optimal design, the optimization platform iterates through thousands of possible samples. To accelerate this process, the platform uses High Performance Computing (HPC) parallelizing the computation work and reducing the calculation time to one or two minutes per sample. Moreover, the optimization software uses sophisticated algorithms that are designed to reach convergence within a minimum number of iterations. To ensure precision, all calculation models have been thoroughly validated by means of measurements on dedicated measurements set-ups and samples. This enables Punch Powertrain to go from customer requirements to matching design in merely two weeks.

The strategic advantage brought by the Multidisciplinary Design Optimization Platform positions us ahead of our competitors, demonstrating the company’s technology leadership and affordability in the field of sustainable powertrain solutions.

All trade-offs are laid bare at the earliest possible stage in the design process. Our in-house developed platform enables us to do just that, delivering immediate value to our customers.

Latest insights & stories

ROAD SAFETY

Since 2018, the number of traffic casualties in Flanders has risen again. Currently, the figures are stagnating, but the risk of accidents with injuries remains high for vulnerable road users in Flanders. And that while traffic should be safe for all users and modes. We want to change this by focusing on transparent policy, training on safe behavior, infrastructure improvements, legislation and enforcement.

What is needed for a more circular construction sector? Insights from Sien Cornillie, Circularity expert at NAV

NAV, or "Netwerk Architecten Vlaanderen," is a professional organisation for architects in Flanders. It offers various services including professional development and advocacy for the architectural sector. NAV also fosters networking opportunities and provides advice on legal, technical, and management aspects. The network is currently working on a position paper on circularity. We sat down with Sien Cornillie, an expert on circularity and energy at NAV. This interview reflects her own opinion.

A Global Movement: The World Unites in a Pink Pledge for Clean and Sustainable Water

5,000 participants. 32 countries. €30,000 funds raised. And that's just the beginning.

Picture this: One step that sends ripples across the globe, transforming lives and creating waves of change. You might wonder, how can such a simple action for most of us have such a profound impact?